Practical introduction: terminal connection selection criteria, connector installation skills and common problem solving

2024-06-27 14:32:50 882

As the cornerstone of electronic and electrical engineering, terminal connectors are the key to their role and diverse functions, which have long gone beyond simple current transmission media. They are not only the bridge of energy and signal transmission, but also ensure the stable operation of equipment and improve the overall reliability of the system. With the continuous progress of technology and the increasing diversity of application needs, a detailed understanding of the internal structure of terminal connectors, material science, connection technology, selection strategies and standardization specifications has become a compulsory course for everyone involved in this field.

It is from this point of view that INFINITECH has carefully compiled a comprehensive guide that combines theoretical depth with practical breadth. We start from the basic composition of the terminal connector, and gradually uncover the mystery of the contacts, insulators, shells and various auxiliary accessories, so that readers have a comprehensive and detailed understanding of this seemingly small but crucial component.

A component of the terminal connector

Contact: This is the core part of the connector and is responsible for the actual current conduction. Contact parts are usually divided into positive contact parts (such as pins) and negative contact parts (such as jacks), which are electrically connected through the coordination of Yin and Yang contact parts. Positive contacts are usually rigid and have cylindrical shapes (round pins), square columns, etc., while negative contacts are designed to accommodate positive contacts.

Insulator: Also known as the base or mounting plate, it is mainly used to fix and isolate the contacts, ensuring good insulation between the contacts and the contacts and the housing. Insulators arrange contacts in an orderly manner and maintain the necessary spacing to prevent short circuits.

Housing: The housing primarily serves a protective role by enclosing insulators and contacts to prevent external physical damage, and may also be designed with aligning devices to ensure that plugs and receptacles are properly connected. The housing can also provide a mechanical fixing point for mounting the connector to the device.

Fixing device: Although the direct reference to "fixing device" is less, it can be understood to include a variety of accessories and mechanisms, such as clasps, positioning keys, screws, nuts, etc., which are used to fix the connector itself or fix the wire to the connector to ensure the stability and reliability of the connection.

Accessories: Includes structural accessories and mounting accessories, such as seals, gaskets, cable clamps, etc., which help to improve the environmental adaptability of the connector, such as water and dust resistance or enhance mechanical stability.

Second, the matching of terminal material and wire material

The selection of terminal material needs to consider the match with the wire material to achieve the best electrical performance. For example, pure copper (bare copper) terminals are usually used with copper wires of the same material because of their excellent electrical conductivity and ductility. This combination is suitable for occasions requiring high conductivity and good flexibility, but it should be noted that copper is easy to oxidize, long-term exposure to the air may affect the quality of the connection, so sometimes coating is used. Tinned copper terminal can provide better oxidation resistance and corrosion resistance, suitable for copper, tinned copper, aluminum and other wires. Tinning can improve the contact between different metals (such as copper and aluminum), reduce electrochemical corrosion, especially suitable for use in wet or corrosive environments.

Copper clad steel or copper alloy terminals This type of terminal combines the excellent electrical conductivity of copper with the high strength of steel and is suitable for connections requiring high mechanical strength. They can be paired with copper wires or wires of other compatible materials, but should be selected with consideration of cost effectiveness and specific application requirements. Nickel, silver or gold plated terminals These high-end coatings improve corrosion resistance and electrical conductivity of terminals, especially gold plated terminals, for high frequency signal transmission or precision connections requiring very low contact resistance. This type of terminal is usually paired with a thin wire diameter copper wire (such as multi-stranded shielded wire) for electronic equipment, communication systems, etc.

The collocation principles are summarized as follows:

-

Ensure compatibility between terminals and wire materials to avoid corrosion problems caused by electrochemical reactions.

-

The material of the terminal must be able to withstand the mechanical stress during the connection process, as well as the vibration and pulling during long-term use.

-

Choose a material combination with good electrical conductivity to reduce resistance and heat loss.

-

Select the right material and coating according to the application environment (such as temperature, humidity, corrosive gases, etc.) to improve durability.

-

Match the size and crimp of terminals and wires according to relevant industry standards (such as UL486A, C, etc.) to ensure the safety and reliability of the connection.

Third, the connection mode of the terminal connector

There are various connection methods for terminal connectors, each of which has its specific application scenarios and advantages and disadvantages.

-

The welding method is suitable for permanent connections that require very high connection reliability and should not be disassembled, such as component connections on electronic circuit boards. The advantage is that it provides a highly stable electrical connection with almost no contact resistance. The disadvantage is that the operation is complex, requires specialized equipment, is difficult to modify once connected, and may increase thermal stress in some applications.

-

Crimping is widely used in power, telecommunications, railway and other industries, especially suitable for high-current connection. Its advantage is that the operation is simple and fast, can form a solid mechanical and electrical connection, suitable for automated production. The disadvantage is that special crimping tools are required, and the crimping quality depends on tool accuracy and operator skills.

-

Screw connections are common in control cabinets, switchboards and other occasions that require frequent changes or maintenance. The advantages are easy to install and disassemble, strong adaptability, and can connect different wire diameters. The disadvantage is that the screws may become loose after a long time of use, and regular inspection is required.

-

Insulated displacement connection (IDC) is suitable for mass production of ribbon cables or thin-walled wires, such as data cables and telephone wires. The advantage is that there is no need to strip the insulation layer of the wire, fast and efficient, suitable for automatic assembly. The disadvantage is that it is not suitable for all types of wires, especially thicker and harder wires, which may damage conductors.

-

Winding is a traditional method that is less used today, but is still in demand in some maintenance situations or specific applications. It is simple and does not require special tools. The disadvantages are low connection reliability, easy to be affected by vibration, and occupy a large space.

Understanding and mastering these methods is the premise of efficient electrical assembly. When choosing the right connection method, you need to consider the reliability, cost, production efficiency, maintainability and application environment of the connection. Different connection methods have their own advantages and are suitable for different engineering and product needs.

Four, the selection standard of terminal connector

The correct selection of terminal connectors requires comprehensive consideration of the cross-sectional area of the wire, material, and use environment. The cross-sectional area of single-core or multi-core conductor is directly related to the current carrying capacity, and the appropriate specifications should be selected according to the circuit design. Material matching, not only to consider the electrical performance, but also take into account the environmental adaptability, such as high temperature, humid environment for the special requirements of the material. In addition, applications in harsh environments also need to consider the protection level of the terminal to ensure long-term stable operation. Here is a guide to some of the key selection criteria:

-

Wire cross-sectional area:

-

The terminal connector must match the cross-sectional area of the wire. Too small a terminal cannot grip the wire firmly, which may lead to poor contact or overheating; Too large terminals may cause loose crimping or waste space. Consult the specifications provided by the manufacturer for the wire diameter range applicable to the terminals.

-

For multi-core wires, it is also necessary to consider whether the terminal supports and can effectively fix multiple strands of wire, and sometimes it is necessary to synthesize multiple strands of wire into a single strand or use a wire nose.

-

-

Wire material: Ensure that the terminal material is compatible with the wire material to avoid electrochemical corrosion. For example, copper wires are often used in conjunction with copper or tinned copper terminals to reduce the risk of oxidation.

-

Use environment:

-

Select terminal connectors with appropriate protection levels (such as IP levels) based on the application environment. Humid, corrosive, high temperature, or vibrating environments may require special materials or fortified terminals.

-

For outdoor or extreme weather conditions, connectors with better weather resistance and tightness should be selected.

-

-

Current and voltage requirements: Select terminals that can withstand the expected maximum current and voltage to avoid safety hazards caused by overload. Refer to the rated current and voltage of the terminal to ensure a safe margin.

-

Connection method: According to the actual operation convenience and cost consideration, choose the appropriate connection method, such as crimping, welding, screw connection, etc. Consider the maintainability and long-term stability of the connection.

-

Installation space and cost: Considering the space limitations of the installation location, choose the appropriate size and shape of the terminal connector. At the same time, balance performance and cost, choose cost-effective solutions.

-

Industry Standards and certifications: Ensuring that the selected terminal connectors comply with relevant industry standards and safety certifications, such as UL, CE, RoHS, etc., is essential for specific industry applications.

Specifications and standards of terminal connectors

The specifications and standards of terminal connectors are the basis for ensuring their compatibility, safety and reliability worldwide. The following is an overview of some of the important international standards, size specifications and rated current and voltage technical parameters compiled by INFINITECH:

-

International standards and certifications:

-

IEC (International Electrotechnical Commission) : published a series of standards for electrical equipment and connectors, such as the IEC 60947 series for switchgear and control equipment.

-

UL (Underwriters Laboratories) : Provides certification to safety standards such as UL 1977 for panel mounted terminals and terminals.

-

DIN (German Industrial standard) : widely used in Europe, such as DIN 19240 on the size and testing of terminal blocks.

-

CE marking: indicates that the product meets the safety, health and environmental protection requirements of the European Union.

-

RoHS (Restriction of the Use of Certain Hazardous Substances Directive) : To ensure that products do not contain certain hazardous substances such as lead and mercury.

-

-

Size specification:

-

The dimensions of the terminal connector usually include the width, length, height of the terminal, and the pitch of the pins or slots (such as pitch). These parameters need to match the on-board interface, cable diameter and installation space in the application.

-

Common size standards include European terminals, PCB terminals, junction box terminals, etc., each with a different size system.

-

-

Rated current and voltage:

-

Rated current: indicates the maximum current that the terminal connector can carry continuously under specified conditions, exceeding this value may cause overheating or fire. Choose with a safety margin.

-

Rated voltage: indicates the maximum voltage that a terminal can safely withstand. Ensure that no breakdown or flashover occurs when the terminal is used at the highest operating voltage of the system.

-

-

Contact resistance and insulation resistance:

-

Contact resistance: A measure of the resistance of the current through the contact point, the lower the better, usually required in the microohm level.

-

Insulation resistance: Evaluate the ability of the insulation material to prevent current leakage. A high insulation resistance value means better electrical isolation.

-

-

Mechanical strength and environmental adaptability:

-

Including tensile strength, insert and remove times, temperature range, dust and waterproof grade (such as IP65, IP67), choose the corresponding protection level according to the use environment.

-

The correct understanding and application of these specifications and standards is essential to ensure the correct selection, safe use and global market compatibility of terminal connectors. When choosing, you should carefully consult the data sheet provided by the manufacturer, which contains all the key parameters and technical details mentioned above.

Six, terminal connector use and installation skills

Preparatory work

Confirm specifications matching: First confirm that the terminal connector matches the specifications of the wire, including the cross-sectional area of the wire, current and voltage rating.

Safety measures: Ensure that the work area is clean and free of debris, use insulation tools, and wear insulation gloves and goggles if necessary.

Removal of insulation

Use a proper tool: Select a proper wire stripper, such as a wire stripper or a wire stripper, and adjust the size of the wire stripper based on the wire diameter.

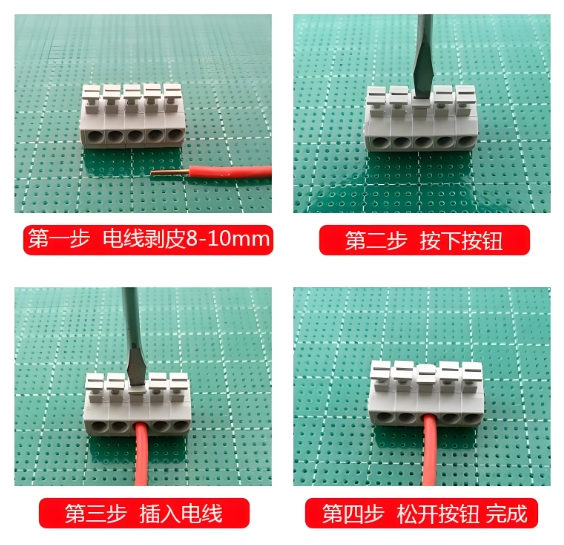

Precise removal: Remove about 8-10mm of the insulation layer at both ends of the conductor to ensure that some of the conductors are straight and without damage. At the same time, avoid removing too much conductor exposure for too long.

Plug in wire

Check conductors: Make sure there are no burrs or damage at the end of the wire, and trim if necessary.

Insert the terminal: Insert the wire correctly according to the terminal type (such as crimping, IDC, and screw fixing). For crimping terminals, use special crimping pliers to align the position and press tightly; For screw fastening terminals, wrap the bare conductor around the screw or use a wire nose.

Fixed terminal

Use a screwdriver: For the terminal connectors secured by screws, use a proper screwdriver to tighten the screws with proper force to avoid damage to the wire core or screws.

Check firmness: gently pull the wire to confirm that it is firmly fixed and not loose.

Test and inspection

Circuit test: Use tools such as a multimeter to check circuit connections and ensure that there is no short circuit or open circuit.

Appearance check: Check whether terminals and connectors are damaged and installed correctly.

Safety and maintenance

Label: Label cables and terminals properly to facilitate subsequent maintenance.

Regular check: Check the terminal connection status regularly. If loose, corroded or damaged, repair or replace it in time.

Technical tips

-

Before crimping, you can slightly bend the wire end to increase the contact area with the terminal.

-

Using the right tools can greatly improve efficiency and safety, and avoid damage caused by mismatched tools.

-

For screw fastening terminals, use a locking glue or lock washer to increase the stability of the connection.

Seven, terminal connector common problems and solutions

Poor contact

- Problem performance: Due to unreasonable contact design, improper material selection, substandard size or improper plating treatment, resulting in increased resistance, may cause heating, signal attenuation or break.

- Solution: Optimize the contact design, select high-quality conductive materials (such as copper alloy, silver plating or gold plating), ensure that the crimping height and crimping strength meet the manufacturer's specifications, and regularly check and maintain the plating.

malfixation

- Symptom: The terminal cannot be firmly fixed on the socket or base, which may cause system failure due to instantaneous power failure or loose connection.

- Solution: Check and ensure that the terminals match the socket size, and use the correct fixing tools and methods, such as adding fixing points or using locking devices.

Appearance defect

- Problem manifestation: the surface of terminals or connectors has peeling, corrosion, scratches, plastic parts have flash, crack, etc., affecting the appearance and electrical performance.

- Solution: Improve the production process, using more durable materials and surface treatment technologies, such as improving mold accuracy, using high-quality plastic raw materials, and optimizing the plating or coating process.

Electrical performance problem

- Problem performance: including insulation performance decline, insufficient voltage resistance, electromagnetic interference.

- Solution: Select insulation materials that meet voltage and environmental requirements, add shielding layers to reduce electromagnetic interference, and ensure that the distance between terminals meets insulation requirements.

Crimp problem

- Problem performance: Improper crimping height, too high or too low, may lead to poor contact or core damage.

- Solution: Calibrate the crimping tool, ensure that each crimping is within the manufacturer's recommended crimping height range, and perform regular maintenance and calibration of the crimping tool.

Welding problem

- Problem performance: weak welding, virtual welding, welding spot is too large or too small.

- Solution strategy: Improve the welding process, such as adjusting the welding temperature, time, pressure, the use of appropriate solder and flux, to ensure that the training of welding operators qualified.

Material matching problem

- Problem performance: Contact of different materials leads to electrochemical corrosion, affecting the connection life.

- Solution: Ensure that the terminal material matches the wire material, avoid direct contact with different metals, and use transition layer or anti-corrosion treatment if necessary.

Eight, terminal connector troubleshooting

INFINITECH summarizes the following solutions for specific failures such as terminal loss, insulation failure caused by PVC thermal shrinkage, and substandard tensile tests:

1. The terminal is disconnected

-

Problem identification: The terminal falls off the wire or out of the connector, which may cause circuit interruption.

-

Treatment method:

-

Check and confirm that the original crimp or connection was performed correctly, and re-crimp or connect if necessary.

-

Make sure the terminals match the wire size and use the correct crimping tools and force.

-

If it is fixed with screws, check whether the screws are loose and tighten the screws to the recommended torque using an appropriate screwdriver.

-

Use locking measures such as Loctite glue or double nuts.

-

2. PVC heat shrinkage problem

-

Problem identification: PVC insulation bushings fail to shrink evenly during heating, or excessive shrinkage leads to exposed wires.

-

Treatment method:

-

Adjust the temperature and distance of the heat gun to avoid local overheating.

-

Use a heat shrink tube of the appropriate diameter to ensure that it matches the wires and terminals.

-

Move the heat gun slowly during heating to ensure even heating.

-

If excessive shrinkage has occurred, it may be necessary to cut off the damaged part and reinstall a new heat shrink tube.

-

3. Tension is not up to standard

-

Problem identification: The wire is easily pulled out from the terminal and does not meet the tension test standards.

-

Treatment method:

-

Check the crimping tool Settings to ensure the manufacturer's recommended crimping height and force are met.

-

For crimping terminals, ensure that the crimping part completely covers the conductor and has no exposed parts.

-

Use wire snouts or stiffeners to enhance wire fixation, especially in high-current or dynamic applications.

-

Pull test again to confirm compliance with relevant standards.

-

General troubleshooting techniques

-

After each connection, document the tools, materials, procedures, and results used to facilitate problem tracing.

-

Ensure that operators are properly trained and familiar with the correct connection methods for different terminals.

-

Regular inspection and maintenance of connectors and tools to avoid problems caused by wear and tear.

-

When storing and operating terminal connectors, pay attention to the environmental conditions to prevent moisture and dust from affecting the connection quality.

Through the above methods, common faults of terminal connectors can be effectively identified and solved to ensure the reliability and safety of electrical connections.