Rare edition diagram! Electronic components LOT NUMBER and D/C form and batch requirements detailed

2024-07-24 14:59:48 1015

In today's electronic product supply chain, there are complex and precise production processes hidden behind every tiny electronic component. To ensure the quality, traceability and consistency of these components, the LOT CODE (batch number) becomes an indispensable technology. LOT CODE not only marks the production process of components, but also carries the trust bridge between manufacturers, distributors and end users. However, the world of LOT CODE is far more complex than it appears on the surface, and it contains valuable information such as production dates, quality levels, and origin, which is an important link between producers and users. Follow INFINITECH to learn more.

1. What is the batch of components

LOT CODE, also known as LOT No., is short for "lot number", derived from the English term lot number. Manufacturers give each batch a unique production number to track and audit the production history of this batch of components. This batch number, a set of numbers or a combination of letters and numbers, is specifically used to identify a particular "batch." Usually, the batch number can be traced back to the detailed production information of the product, including the date of production, quality grade, time of manufacture, and place of origin. At present, many companies are gradually standardizing the production date and batch number of components to improve traceability efficiency. It is worth noting that the LOT NUMBER format used by different manufacturers and its representation with Date/Code (D/C) will vary.

2. Sample silk screen printing of component products

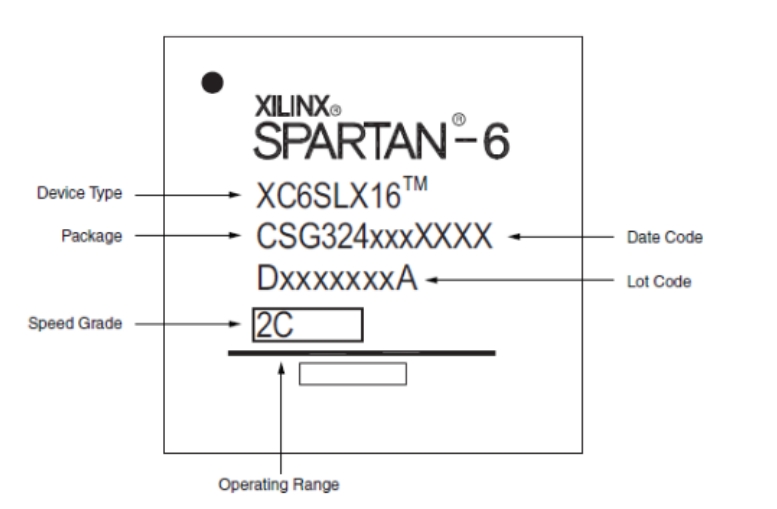

Figure 1

Figure 1

The Xilinx Logo is shown in Figure 1; Family Brand Logo; The first line is the product model screen; The second line includes package, bare chip version, fab code, D/C, etc.; The third line represents the location and batch information with 10-character LOTCODE

Figure 2

Figure 2

Figure 2 shows the chip screen printing information of CYPRESS; 1, 2 behavior models, line 3 is D/C and lot number, line 4 is the origin

Figure 3

Figure 3

Figure 3 shows the example of TI chip screen printing, Lot trace code, where YM is assembly time D/C, LLLL is assembly factory

Figure 4

Figure 4 shows a LOT NUMBER printed on the outer package and a LOT CODE containing batch and origin information

Figure 5

Figure 5

Figure 5 shows the description of Altera LOT number, including package test plant code, bare chip version information, D/C information, etc

Figure 6

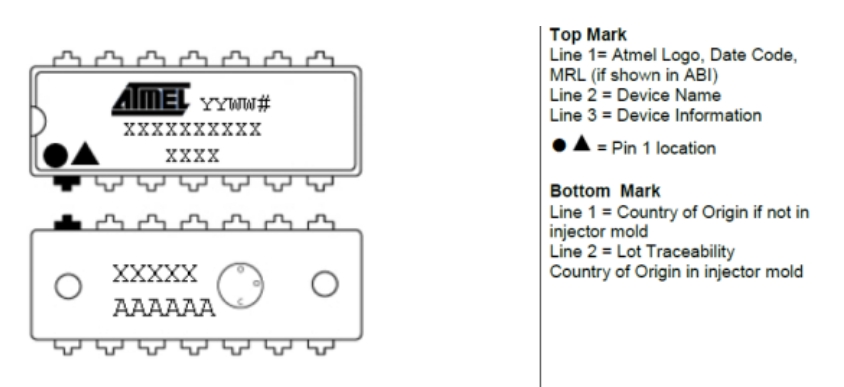

Figure 6

Figure 6 shows the Atmel screen printing information, the top screen printing is D/C, product information, and the bottom screen printing contains a LOT of NUMBER of places of origin

Figure 7

Figure 7

Figure 7 shows a LOT of SPANSION information including D/C, assembly location, etc

FIG. 8

FIG. 8

Figure 8 shows the Micron screen printing style, which contains a LOT of information such as D/C, origin, and bare piece version

Figure 9

Figure 9

Figure 9 shows that the Label Content of Micron LRDIMM series products contains a lot of numbers such as D/C and assembly place

Figure 10

Figure 10

Figure 10 shows the Lattice Datecode (LotID) Format

Figure 11

Figure 11

Figure 11 shows the LT D/C LOT number form

FIG. 12

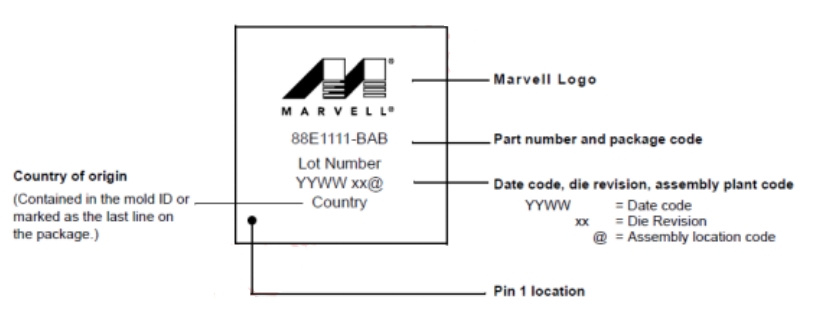

FIG. 12

Figure 12 shows the Marvell LOTnumber D/C silk screen form

FIG. 13

FIG. 13

Figure 13 shows the schematic Pericom lot number, which includes factory code, bare chip version, D/C, fab code, etc

FIG. 14

FIG. 14

Figure 14 shows ST D/C origin and other information.

Third, batch information representation

Batch, is the same batch of raw materials, in the same shift and the same production line produced by the same variety and the same specification of products, for a batch. Relative to the narrow sense of components, it is the production date of the screen printing on the surface of the chip in the package test factory or the date on the outer package label. We believe that the batch is DTAE CODE, referred to as D/C, in general, the batch information of components is expressed:

a. Denote the year Y with a single letter.

FIG. 15

FIG. 15

In Figure 15, the D/C silkscreen on the EPSON crystal uses the corresponding letter to represent the last digit of the natural year, such as 2006 or 2016 with F.

b. Use one character to represent the year (Y/W).

Figure 16

Figure 16

Figure 16 shows the HP RF transistor D/C screen printing mode. The five-year cycle is used, and D represents January 1999, January 2004, January 2009, etc.

c. Use two characters to represent the year (Y/W).

Figure 17

Figure 17

Figure 17 shows the silkscreen information ON the chip, Y:Year Date Code, W: WorkWeek Date Code.

Figure 18

Figure 18

As shown in Figure 18: ON is the code of the year and week for the silkscreen characters. The left part of the figure is the year and the right part is the week. For example, KD indicates the fourth week of 2007.

d. Use two characters to indicate the year (Y/M).

Figure 19

Figure 19

Figure 19 shows the TI chip silkscreen information, Lot trace code, where "97" represents D/C information, 9 is the year code, 7 is the month code

e. Use three characters to represent the year (Y/WW).

FIG. 20

Figure 20 shows the Maxim chip silk screen legend, YWW represents D/C, year week form, for example, 927 represents 2009 week 27.

f. Use 4 characters to represent the year (YY/WW).

Figure 21

Figure 21

In Figure 21, an example of Infineon's chip screen printing, the last 4 characters in line 2 represent D/C, such as 0525 for the 25th week of 2005.

Four, about the "batch" common problems

In our daily work, we often encounter specific requirements from customers for product batches, such as wanting all products to come from the same batch, or requiring product batches to be within a few years. This may raise the question: Why do customers have these special batch requirements for seemingly identical products?

In fact, the reason why customers have such a demand is mainly due to the consideration of product quality consistency, traceability and supply chain stability. Using the same batch of products can ensure consistency of performance and specifications, reducing problems caused by batch differences; The requirement of batch year is to avoid the use of expired or close to the warranty period of stock, to ensure the best condition and reliability of the product. These requirements reflect the customer's high attention to product quality and the importance of long-term partnership.

Same batch overview:

In the production of components, although the design drawings, software, raw materials and production processes are consistent, there may still be slight differences in the actual quality and performance of each batch of products due to different wafer manufacturing, foundry and packaging and testing links. However, the use of the same batch of components means that they have undergone the same parameter setting, production process, assembly environment, MSL (moisture sensitivity level) standards, and welding technology, which greatly ensures the uniformity and reliability of chip performance.

Especially in the military and aerospace sectors, customers have high demands on components, which are driven by the fact that their products operate in extreme environments and have no tolerance for error. Given the high value and potential risks of such products, the failure of any component could have catastrophic consequences. Therefore, before the domestic aerospace products are stored, the key components must be tested by DPA (destructive physical analysis). This test requires random samples from the same batch of products that are completely consistent to ensure the representativeness of the test results and the consistency of the parameters of subsequent production materials, so as to ensure the quality and safety of the entire product.

Therefore, the use of the same batch of components is not only the pursuit of product performance consistency, but also the strict control of the safety and reliability of the final product, especially in those high-end applications with demanding quality requirements.

Why batches will require within a few years:

Under normal circumstances, each product has its warranty period, for electronic components, the warranty period refers to the completion of packaging from the packaging factory and factory, under the specified storage and transportation conditions, the components can guarantee the normal function of the period. The production batch of components is directly related to whether the batch material is in the valid warranty period. Improper storage or transportation conditions, as well as non-standard opening operations, can cause components under warranty to suffer from humidity damage or pin oxidation, which can appear during the welding process, causing false welding, and even damage the chip itself.

In China, many manufacturing enterprises tend to choose components with a production date within two years, which are mainly distributed in the industrial and civil fields. Compared to military standards, they require slightly less product stability, but also allow for some degree of error rate. However, in order to continue to improve product quality, win market competitiveness and good reputation, many companies choose to limit the production date of components within two years. This can effectively prevent the chip during sales and storage, due to external factors such as temperature, humidity changes and lead to performance degradation, thereby reducing product hazards caused by material quality problems. In addition, the use of older batches of materials, once there is a failure, due to the distance from the production date, it may have changed hands many times, it is difficult to trace the original transaction chain, and it will become difficult to seek technical support from the original factory. Therefore, controlling material batches helps maintain supply chain transparency and product reliability.

Five, the role of a Lot of number

In the circulation and application of chips, Lot Number is one of the key certificates for after-sales support, especially when a situation occurs after the use of chips.

When the original factory receives feedback from the end user about the quality of the batch product, the batch number becomes the core tool to trace the production history and product flow. It not only helps the original factory to confirm the production details of the specific batch, but also can quickly locate the affected products after finding quality problems, so as to take timely and effective countermeasures.

It is also important for distributors to record batch number information for purchases and sales, which is an important step to protect their rights. In the spot market, the same type of chip may come from multiple sources, and differences in price, batch, packaging and supply status make procurement complex and variable. When a customer has questions about the quality or origin of a product, verifying whether the product is from the company's sales records through the lot number can help clarify the attribution of responsibility. If it is confirmed that the product is indeed supplied by the company, the distributor can trace the specific source of purchase through the batch number, so as to facilitate communication with the supplier and solve potential problems.

For end customers, recording the lot numbers of materials provided by suppliers helps optimize inventory management. In the production process, priority is given to the consumption of earlier batches of chips to ensure that the rest of the inventory is the latest batch, which avoids resource waste and improves the stability of product performance. In addition, once problems are encountered in use, customers can quickly identify the supply source through the batch number, trace back to the original factory along the transaction link, accelerate the problem diagnosis and solution process, and ensure the smooth and efficient supply chain.

Therefore, whether it is the original factory, distributor or end user, the accurate recording and management of Lot Number plays a significant role in all aspects of the process, which promotes product quality control, supply chain transparency and after-sales service optimization.