In-depth understanding of the structure and classification of magnetic beads: the power and selection guide of anti-interference components

2024-01-16 16:21:55 169

The full name of magnetic beads is ferrite bead filter (there is another kind of magnetic beads made of amorphous alloy magnetic material). It is an anti-interference component and has a remarkable effect in filtering high-frequency noise. The main raw material of magnetic beads is ferrite. Ferrite is a ferrimagnetic material with a cubic lattice structure. Ferrite material is iron-magnesium alloy or iron-nickel alloy. Its manufacturing process and mechanical properties are similar to ceramics, and its color is gray-black. Magnetic beads have high resistivity and magnetic permeability, which is equivalent to a resistance and inductance in series, but the resistance and inductance values change with frequency. It has better high-frequency filtering characteristics than ordinary inductors. It is resistive at high frequencies, so it can maintain a high impedance in a fairly wide frequency range, thus improving the frequency modulation filtering effect. The circuit symbol of the magnetic beads should not be drawn as an inductor. It is recommended that the schematic diagram identification and bit number be different so that readers of the diagram can easily see that the magnetic beads are used.

1. Model naming method of magnetic beads

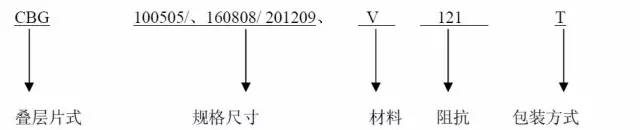

The model of magnetic beads generally consists of the following five parts:

Part 1: Category, mostly represented by letters.

Part 2: Dimensions, expressed in numbers (imperial)

Part 3: Materials, represented by letters, where X stands for small.

Part 4: Impedance, impedance at 100MHz

Part 5: Packaging method, represented by letters

For example, a certain model of magnetic beads is named as follows:

Ferrite laminated chip magnetic beads (ordinary type)

Ferrite chip beads

Size: 1005 (0402) 1608 (0603) 2012 (0805)

Product specification naming method:

It should be pointed out that the current naming methods of magnetic bead models vary from manufacturer to manufacturer, and there is no unified standard.

2. Structural characteristics of magnetic beads

Ferrite Bead is an anti-interference component that is rapidly developing in application. It is cheap, easy to use, and has a remarkable effect in filtering high-frequency noise. In the circuit, you only need to pass the wire through it (the ones I use are like ordinary resistors, the wire has been passed through and glued, and there are also surface mount forms). When current passes through the wire, the ferrite has little resistance to low-frequency currents, but has a greater attenuation effect on higher-frequency currents. The high-frequency current is dissipated in it as heat, and its equivalent circuit is an inductor and a resistor in series, with the value of both components proportional to the length of the magnetic bead. There are many types of magnetic beads, and manufacturers should provide technical specifications, especially the curve of the impedance of the magnetic beads versus frequency. Some magnetic beads have multiple holes. Passing wires through them can increase the component impedance (the square of the number of times the magnetic beads pass through). However, the increased noise suppression capability at high frequencies cannot be as much as expected, and using multiple series connections A few magnetic beads would be better.

Ferrite is a magnetic material, which will cause magnetic saturation due to excessive current, and the magnetic permeability will drop sharply. Large current filtering should use specially designed magnetic beads, and attention should also be paid to its heat dissipation measures. Ferrite beads can not only be used to filter high-frequency noise in power circuits (can be used for DC and AC output), but can also be widely used in other circuits, and their size can be made very small. Especially in digital circuits, since the pulse signal contains high-frequency harmonics, which is also the main source of high-frequency radiation in the circuit, magnetic beads can play a role in this situation. Ferrite beads are also widely used in noise filtering of signal cables.

3. Unit of magnetic beads

The unit of magnetic beads is ohms, not Hunters, so please pay special attention to this. Because the unit of a magnetic bead is nominally based on the impedance it produces at a certain frequency, the unit of impedance is also ohms. The DATASHEET of magnetic beads generally provides frequency and impedance characteristic curves. Generally, 100MHz is used as the standard, such as 600R@100MHz, which means that at a frequency of 100MHz, the impedance of the magnetic beads is equivalent to 600 ohms.

4. Main characteristic parameters of magnetic beads

1. DC resistance DCResistance (mohm): The resistance value of this magnetic bead when DC current passes through this magnetic bead.

2. Rated current RatedCurrent (mA): Indicates the maximum allowable current when the magnetic bead is working normally.

3. Impedance [Z]@100MHz (ohm): This refers to AC impedance.

4. Impedance-frequency characteristics: a curve describing the change of impedance value with frequency.

5. Resistance-frequency characteristics: a curve describing the change of resistance value with frequency

6. Inductive reactance-frequency characteristics: a curve describing the change of inductive reactance with frequency.

The figure below shows the characteristic parameters and frequency characteristic curve of a certain manufacturer’s magnetic beads:

5. Classification and selection of magnetic beads

According to the application of magnetic beads, magnetic beads can be roughly divided into ordinary type, high current type, peak type, etc.

Ordinary type: Ordinary type magnetic beads are used when the current is not too large (generally less than 600mA) and there are no special requirements. Its DC resistance is generally a few tenths of ohms. It can effectively suppress and absorb electromagnetic interference and radio frequency interference from electronic equipment. Its impedance range is generally from a few ohms to several thousand ohms.

Large current type: This type of magnetic beads is used in situations that require larger currents. Since it is used in large current situations, its DC resistance must be very small, about an order of magnitude smaller than ordinary magnetic beads, and its impedance value Also generally smaller.

Spike type: The characteristic of this type of magnetic beads is that in a certain frequency area, its impedance rises sharply, so that a high attenuation effect can be obtained in a specific frequency area without affecting the signal.

(2) Selection of magnetic beads

Magnetic beads are mainly used for EMI differential mode noise suppression. Its DC impedance is very small, but it has high impedance at high frequencies. Generally speaking, 600R refers to the impedance value at the test frequency of 100MHZ. Two aspects should be considered when choosing magnetic beads:

One is the situation of noise interference in the circuit,

The second is the amount of current that needs to pass.

To roughly understand the frequency and intensity of noise, the frequency impedance curves of different magnetic beads are different. Choose the magnetic bead with higher impedance at the center frequency of the noise. If there is a lot of noise interference, choose one with a higher impedance, but the higher the impedance, the better, because the higher the impedance, the higher the DCR, and the greater the attenuation of the useful signal. But generally there are no very clear calculation and selection standards. It mainly depends on the actual use effect. 120R-600R

Commonly used among them. Then it depends on the size of the passing current. If it is used in the power line part, you should choose a model with a larger rated current. If it is used in the signal line part, the rated current requirement is generally not high. In addition, the larger the impedance of magnetic beads, the smaller the rated current. The selection of magnetic beads should be based on actual conditions.

For example, for a 3.3V, 300mA power supply, it is required that 3.3V cannot be lower than 3.0V, then the DC resistance DCR of the magnetic bead should be less than 1R. In this case, 0.5R is generally selected to prevent parameter drift. As for the noise suppression capability, if the noise of 100MHZ and 300mVpp is required to reach the level of 50mVpp after passing through the magnetic beads, assuming the load is 45 ohms, then you should choose 225R@100Mhz, DCR<1R magnetic beads, and 225R How was it calculated?

(45ohm/50mV)*250mV=225ohm

First of all, you need to know the frequency band of the noise you want to filter out, and then choose an appropriate impedance in that frequency band (the actual impedance can be obtained through simulation, and the simulation model can be obtained from the manufacturer). The second step is to determine the circuit. Determining the maximum current flowing through the circuit and the current flowing through the circuit also means that you need to choose a magnetic bead with a rated current. The next step is to determine the DCR (DC resistance) of the magnetic bead, which can be calculated based on the voltage supply range of the subsequent circuit. The range of DCR allowed for magnetic beads. Encapsulation can be selected according to the situation. But it should be noted that the impedance of the magnetic beads is slightly different from that in the specification after you apply voltage.

To correctly select magnetic beads, you must pay attention to the following points:

1. What is the frequency range of the unwanted signal?

2. Who is the source of the noise?

3. How much noise attenuation is required;

4. What are the environmental conditions (temperature, DC voltage, structural strength);

5. What is the circuit and load impedance;

6. The role of magnetic beads

The shape of magnetic beads is similar to that of inductors, and its main function is simply to be interfered by noise on power supply and signals.

At low frequencies, the impedance consists of the inductive reactance of the inductor. R is very small at low frequencies. The magnetic permeability of the magnetic core is high, so the inductance is large, L plays a major role, the electromagnetic interference is reflected and suppressed, and the loss of the magnetic core is small at this time. The entire device is a low-loss, high-Q inductor. This kind of inductance can easily cause resonance. Therefore, in the low frequency band, it may sometimes occur after using ferrite beads. The phenomenon of enhanced interference.

In the high frequency band, the impedance is composed of resistance components. As the frequency increases, the magnetic permeability of the magnetic core decreases, causing the inductance of the inductor to decrease and the inductive reactance component to decrease. At this time, the loss of the magnetic core increases and the resistance component increases, resulting in an increase in the total impedance. When high-frequency signals pass through ferrite, electromagnetic interference is absorbed and converted into heat energy and dissipated.

Ferrite beads are widely used in printed circuit boards, such as at the entrance end of power cords on printed boards. By attaching magnetic beads (larger magnetic rings), high-frequency interference can be filtered out. Ferrite magnetic rings or magnetic beads are specially used to suppress high-frequency interference and peak interference on signal lines and power lines. It also has the ability to absorb interference from electrostatic discharge pulses.

Inductors are energy storage components, while magnetic beads are energy conversion (consumption) devices. Inductors are mostly used in power supply filter circuits, focusing on suppressing conductive interference; magnetic beads are mostly used in signal circuits, mainly for EMI (electromagnetic compatibility). Magnetic beads are used to absorb ultra-high frequency signals, such as in some RF circuits, PLLs, oscillation circuits, ultra-high frequency memory circuits, etc. All need to add magnetic beads to the power input part.

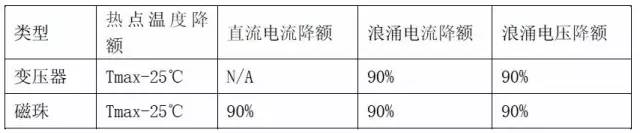

7. Derating of magnetic beads

Magnetic device derating standards